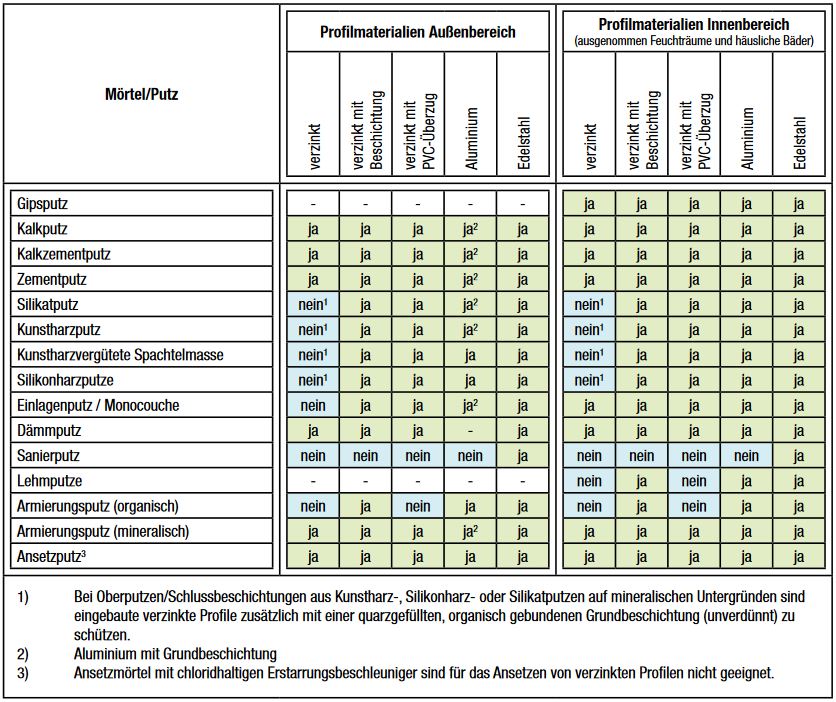

Das Schneiden von verzinkten Profilen muss ausschließlich mit Handblechschere erfolgen, keinesfalls mit Trennschleifer (Korrosionsgefahr). Beim Trennen von Edelstahlprofilen mit Trennschleifer sind die geeigneten Trennscheiben zu verwenden, um eine Oberflächenbeschädigung zu vermeiden. Über Kanten der Edelstahlprofile darf nicht mit Werkzeugen aus blankem oder verzinktem Stahl abgezogen werden, da sonst Kontaktkorrosion auftreten kann. Profile können mit mineralischen Ansetzmörtel oder dem anzuwendenden Putzmörtel (mineralischer Unterputz oder Einlagenputz) angesetzt werden. Der Putzgrund muss trocken, sauber und entsprechend den Anforderungen der verwendeten Putzsysteme saug- und tragfähig sein. Die Wandoberfläche darf keine Salze oder Schadstoffe enthalten. Für Feuchträume, Außenputzflächen, Flächen mit Zement-Kalkzement, Putz- und Mauerbinder-Verputzung sind keine gipshaltigen Materialien zu

verwenden. Für die Markierung der Profile wird ein schnellbindender Ansetzmörtel auf Zementbasis empfohlen.

Für folgende Einsatzfälle empfehlen wir die Verwendung von Edelstahlprofilen:

- im Außenputzbereich bei stark witterungsbelasteten Fassaden und bei Verarbeitung von Wärmedämmverbundsystemen

- auf Winterbaustellen und in der Altbausanierung, wo mit langen Abtrocknungszeiten und Baukörperfeuchte zu rechnen ist

- im erdnahen Sockelbereich mit Gefährdung durch Spritzwasser und Dauernässe

- bei Verwendung von Sanierputzen

- im Sanitärbereich, Küchen, fensterlosen Lagerräumen, Keller, Bereichen mit wiederkehrender Feuchtigkeitseinwirkung,

in Hallenbädern, Saunen nur bedingt einsetzbar (vollständige Überdeckung mit Putz, Farbe bzw. Fliesen

Weitere Informationen für Planung und Anwendung von Putzprofilen finden Sie auch im entsprechenden Merkblatt des Europäischen

Fachverband der Putzprofilhersteller EUROPROFILES

Mitglied von:

Produktinformation gilt in Verbindung mit dem Merkblatt von Europrofiles.

Gesondert anfordern oder unter www.schiwa-profile.de herunterladen