- facing shells

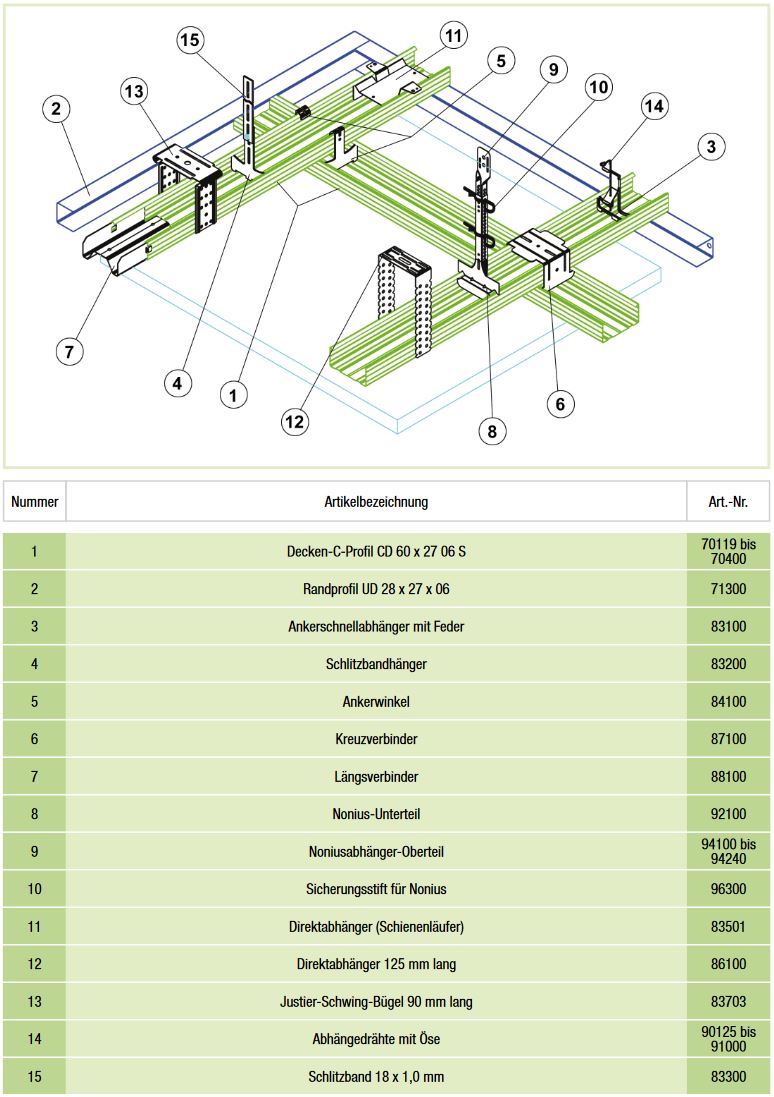

- 1 facing formwork with UD edge profile and CD ceiling profile

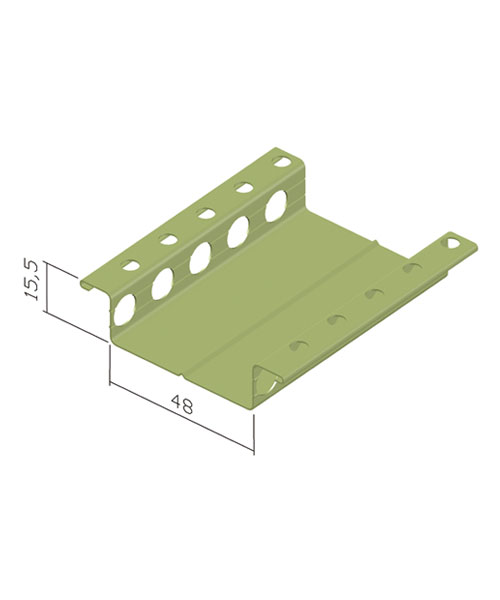

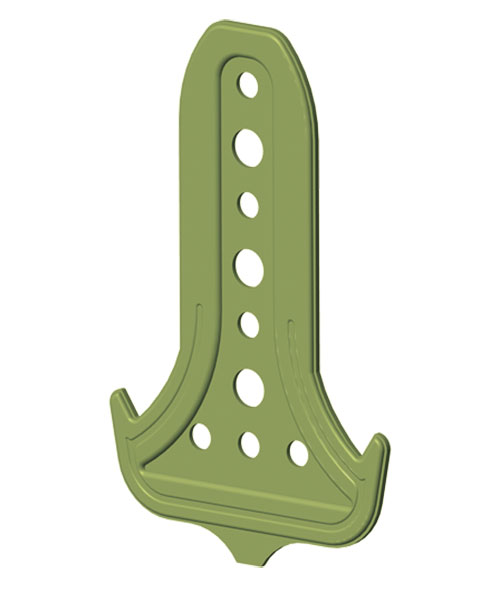

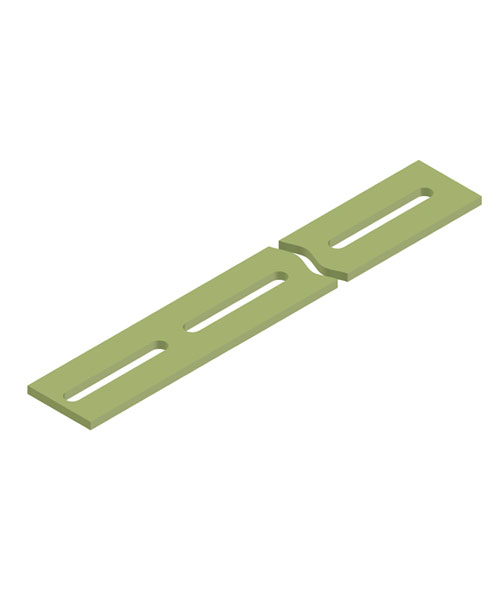

Use a laser, straightedge or chalk line to mark out the course of the wall on the floor and ceiling. Cut U-edge profile, art. no.: 71300, 71400 to length, apply self-adhesive insulating strips, art. no.: 91050 to the back and attach to the floor and ceiling at a maximum distance of 80 cm. Attach direct hangers, art. no.: 85100, 86100 at a distance of 62.5 cm in the middle and bend over. Alternatively, adjustable swing brackets, art. no.: 83700 … 83703, are also suitable. 83703. Insert insulation as required. After cutting the CD ceiling profiles to length, art. no.: 70260 … 70400, the profiles are inserted into the U-edge profile and fastened to the legs of the direct hangers or adjustable swing brackets. Then bend or cut off the protruding legs of the

Direct hangers.

Fasten GK boards at 25 cm intervals using drywall screws.

Fill and sand the joints flush with the surface.

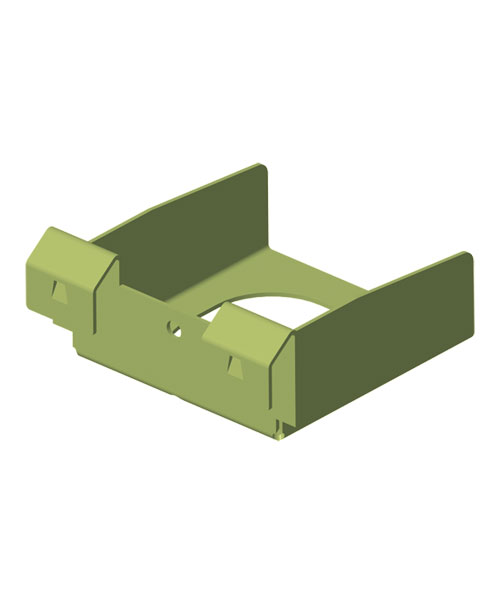

1.2 Free-standing facing formwork with metal stud frame

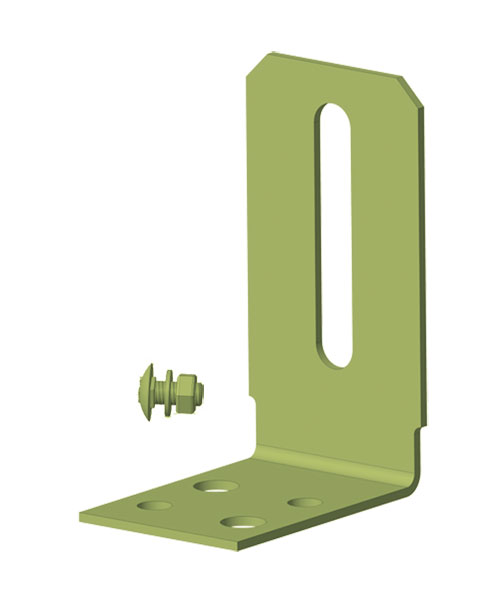

Use a laser, straightedge or chalk line to mark out the course of the wall on the floor and ceiling. Cut U-wall profile UW 75, art. no.: 74400 or UW 100, art. no.: 75400 to length, apply self-adhesive insulating strips, art. no.: 91070 or 91095 to the back and fix to the floor and ceiling. Insert the C-frame profiles CW 75, art. no.: 78250 … 78500 into the U-wall profile UW75 or UW 100 and fasten with drywall screws. Insert insulation if required. Fix GK boards at a screw spacing of 25 cm using drywall screws. Fill and sand the joints flush with the surface.

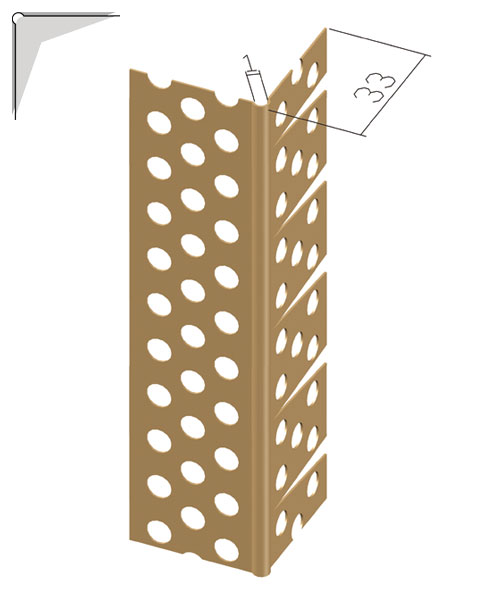

1.3 Facing formwork with drywall hat profile

The drywall hat profile, art. no.: 9255, is attached directly to the wall surface at a distance of 45 cm using attachment mortar. The profiles must be installed as follows:

1. One profile is installed horizontally in the ceiling and floor area.

The distance to the ceiling or floor should be approx. 5 cm.

2. Depending on the GK panel width, the vertical profiles are then inserted between the horizontal profiles.

A distance of approx. 5 cm should be kept from the horizontal profiles for the installation of empty conduits.

3. Once the mortar has hardened, the GRP panels can be fixed with drywall screws.

4. Fill and sand the GRP joints.

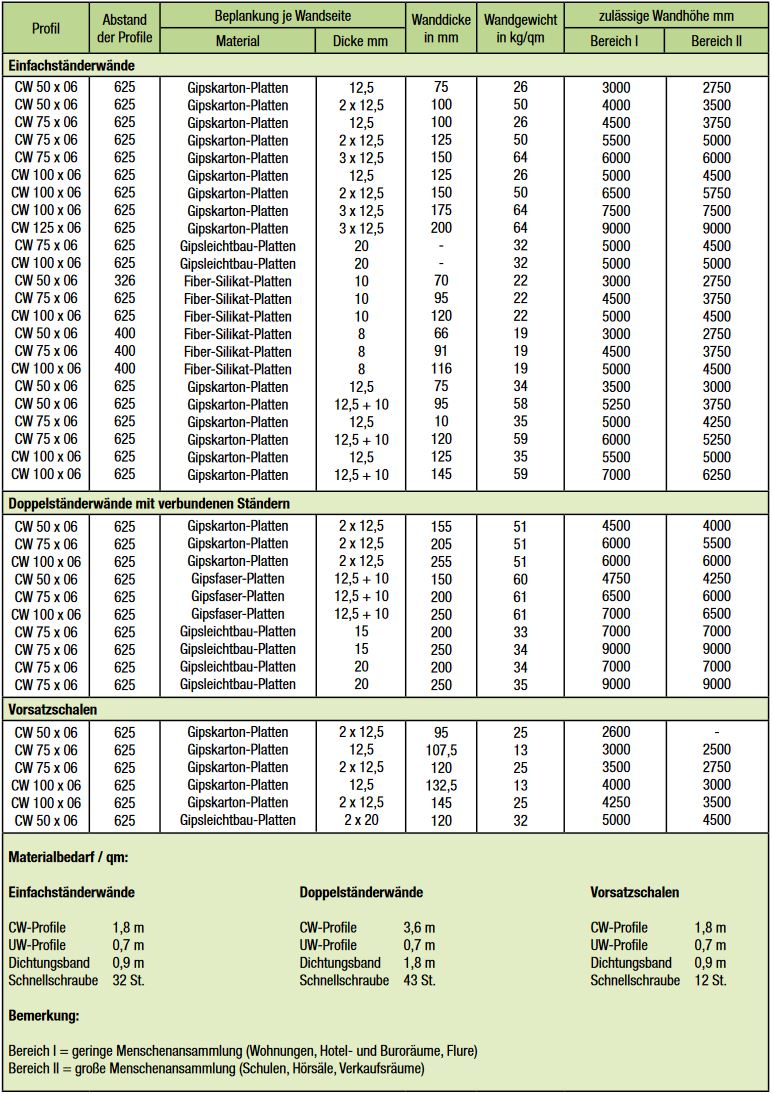

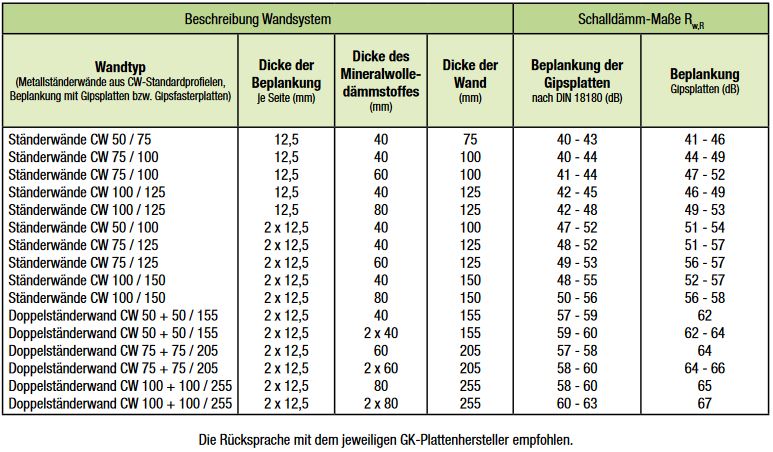

2. free-standing metal stud walls

Use a laser, straightedge or chalk line to mark out the course of the wall on the floor and ceiling.

Cut the U-wall profile UW 50 to UW 100 to length, apply self-adhesive insulating strips to the back and attach to the floor and ceiling.

Insert the C-frame profiles CW 50 to CW 100 into the corresponding U-wall profile UW 50 UW 100 and fasten with drywall screws.

Insert insulation if required.

Fasten GK boards at a screw spacing of 25 cm using

drywall screws.

For double to triple planking, the GK boards must be offset.

Fill and sand the joints flush with the surface.